"Electronic Sorting System"

The electronic sorting system "FLEXSORT" enables optimal sorting of fruits and vegetables based on variables such as weight, color, diameter, length, area, etc.

Its main strengths are its ruggedness, reliability, and ease of use, allowing for quick and easy access to information. Key aspects such as modularity and scalability are also noteworthy. Additionally, its high processing speed stands out, reaching up to 30 fruits per second per calibration line, depending on mechanical limitations.

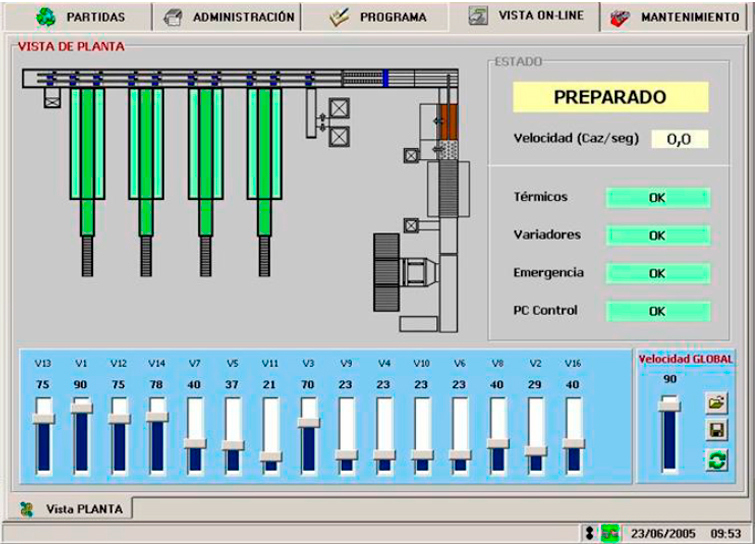

In addition to sorting tasks and defective product detection, it offers a range of additional functions that are highly useful for optimal calibration work. These include automatic speed adjustment, container filling control, detection and correction of mechanical issues (chain stretching, detection of faulty cups, automatic lubrication, precise activation of electromagnets to extend their lifespan significantly, etc.). It also allows for the export of calibration data to traceability systems or internal production management and provides remote access to the data through the internet.

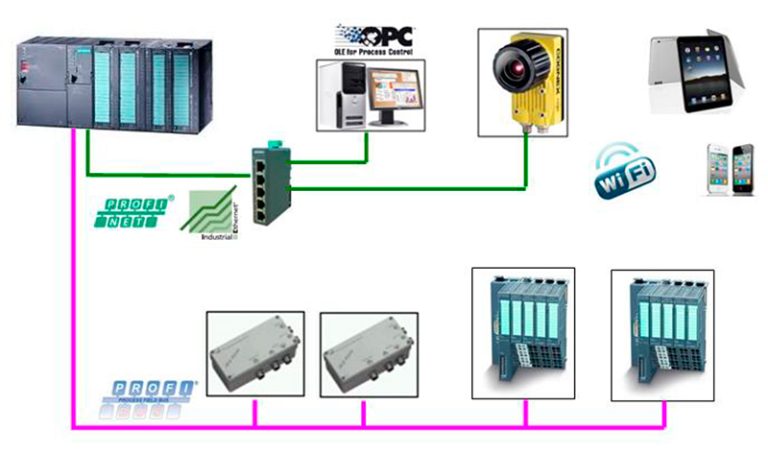

Our "FLEXSORT" solution is entirely based on industrial hardware to guarantee maximum system ruggedness and is totally independent of the operating PC, a typical example of our architecture:

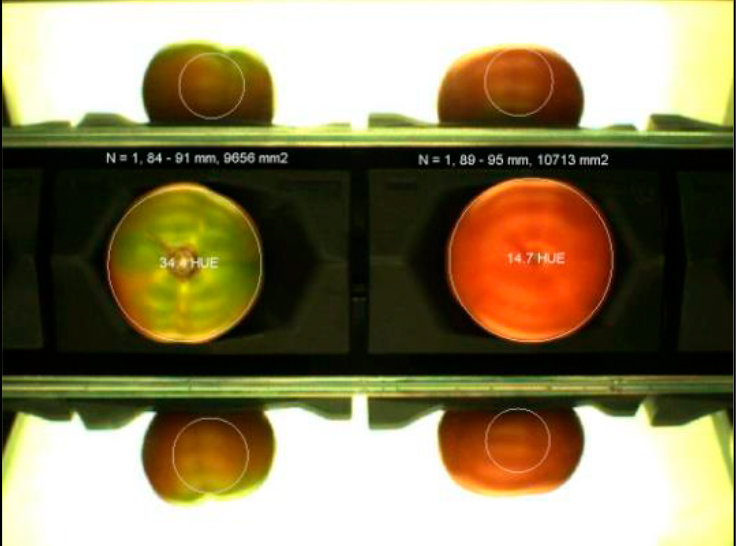

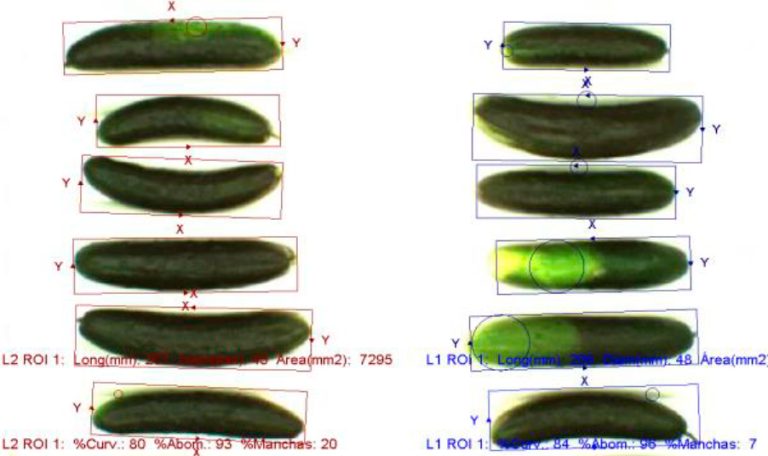

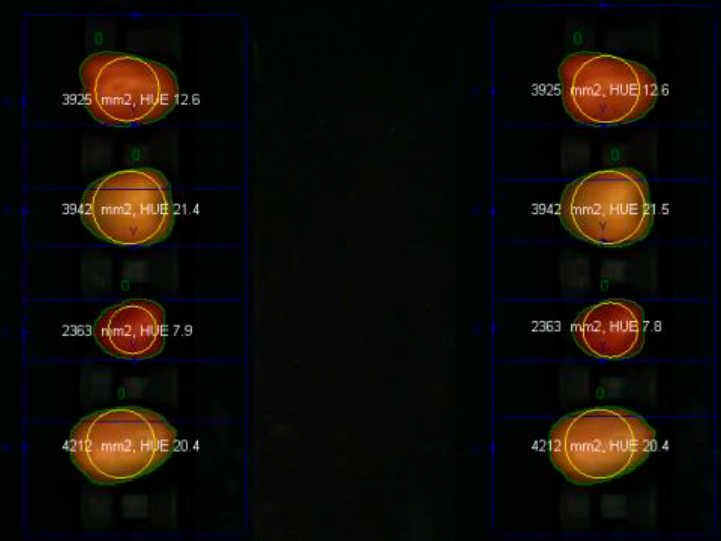

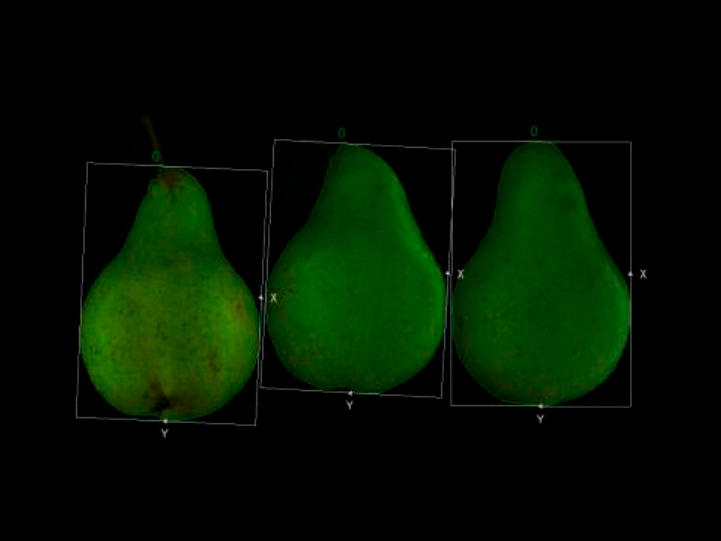

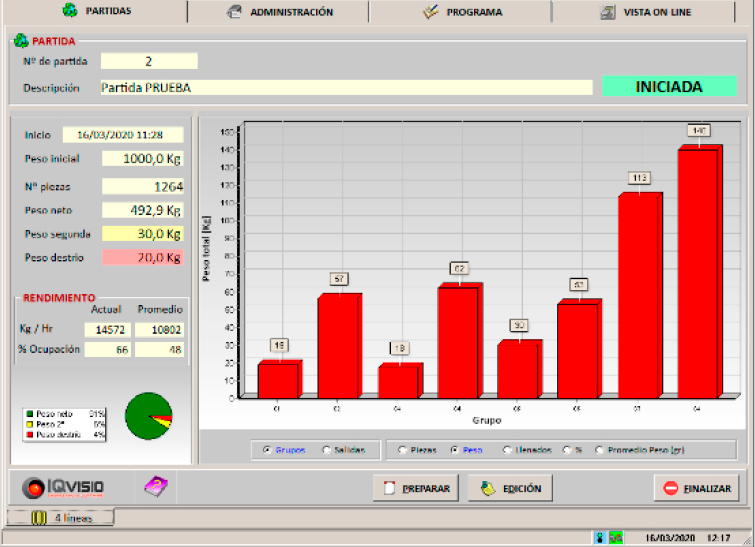

Some possibilities of the FLEXSORT software:

According to requirements, the system allows product sorting by means of various parameters or combinations of them, in a totally intuitive and simple way for the user, who can modify them at will: