Complementary equipment designed for fruit/vegetable handling, in order to maintain quality for commercialization and consumption.

These machines are designed to improve global performance of fruit/vegetable logistics.

Share on:

DEPALLETIZER

AUTOMATIC PACKAGING MACHINE

STRAPPING MACHINE

CRATE WASHER

SEEDING LINE

PALLETIZER

DEPALLETIZER

Depalletizing line

Depalletizing line

- Thermo-lacquered iron structure.

- Speed of 10 minute cycles

- Customized software.

- Multiformat depalletizing methods

- Option to feed several machines simultaneously

- Interaction with production line processes

- Safety elements with perimeter fencing and anti-collision system.

- Available for fruit and vegetables handling.

- User-friendly touch screen (HMI) with parameter setting.

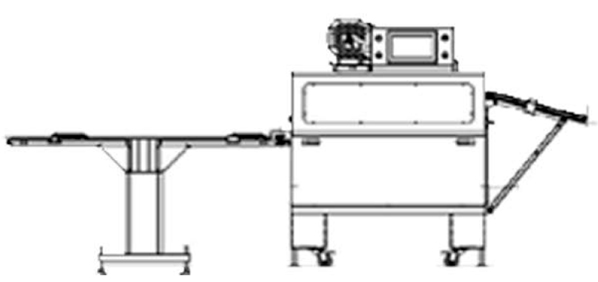

AUTOMATIC PACKAGING MACHINE

AUTOMATIC PACKAGING MACHINE

- Up to 25 packages per minute

- Packages sizes up to 380 X 230 X 150mm

- Packages weighing up to 50kg

- Wrap up to 550mm wide

STRAPPING MACHINE

Semiautomated

Automated

CRATE WASHER

CRATE WASHER

- Easy integration to any existing system

- Spray washing

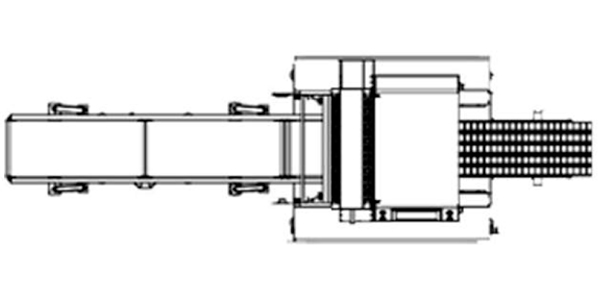

SEEDING LINE

SEEDING LINE

- Up to 600 trays per hour

- Tray size 700 X 480 X 130 mm

- Compressed air dryer

- Manufactured in black Steel coated with electrostatic paint

PALLETIZER

Cartesian Multiform Palletizing Line

- Thermo-lacquered iron and stainless-steel structure.

- Power of 7 kw, with an average production of 4 cycles/min.

- Different types of box selection: manual, barcode, RFID and vision.

- Air consumption: 80 litres/minute.

- Horizontal and vertical movement managed independently by an electronic controller.

- Access controlled by barrier and self-anchoring system.

- Formats can be customized by the user on touch screen.

- Available for fruit and vegetables handling.

- User-friendly touch screen (HMI) with parameter setting.

Robotic Palletizing Line

- Thermo-lacquered iron and stainless-steel structure.

- Up to 10 cycles per minute.

- Rfid pallet identification system for traceability tracking from the field to the production lines.

- Customized software.

- Multi-format palletizing.

- Safety elements with perimeter fencing and anti-collision system.

- Interaction with various processes in the production line.

- Available for any type of palletizing process.

- User-friendly touch screen (HMI) with parameter setting.